Crucial Considerations for Choosing the very best Engine for Your Requirements

In the realm of picking the excellent engine to meet your requirements, a number of critical variables demand careful consideration to guarantee ideal efficiency and effectiveness. From the nuanced equilibrium in between power and performance to the often-overlooked elements of upkeep and solution needs, each element plays a pivotal role in identifying the most appropriate engine for your particular requirements.

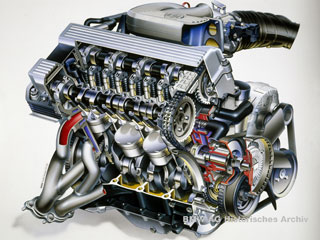

Power and Performance

When examining engines for ideal performance, it is vital to focus on both power outcome and effectiveness. Power outcome determines the capability of an engine to produce energy, which directly impacts its efficiency. A high power result is essential for requiring jobs such as sturdy applications or high-speed needs. It makes sure that the engine can manage the work efficiently and efficiently. Power alone is not sufficient; performance plays a substantial function in figuring out the overall efficiency of an engine. Effectiveness refers to just how well the engine transforms fuel into usable power. A much more efficient engine will certainly supply much better mileage, reduced discharges, and decreased operating expense. Striking the appropriate balance between power outcome and efficiency is vital to choosing an engine that meets your certain needs. It is vital to take into consideration aspects such as the intended use the engine, environmental influence, and long-term expense implications when making this choice. By thoroughly evaluating both power and effectiveness, you can pick an engine that delivers ideal efficiency and meets your demands effectively.

Fuel Efficiency and Economic Climate

Fuel performance refers to the engine's capacity to transform gas into energy with minimal waste, directly influencing operating costs and ecological sustainability. Engines with greater gas efficiency not just lower gas expenses yet additionally reduce carbon emissions, contributing to a greener operation.

Compatibility and Application

Taking into consideration the fuel effectiveness and economic situation of an engine, the next important facet to address is its compatibility and application within particular functional contexts. Compatibility refers to just how well the engine integrates with the overall system or devices it powers.

In addition, the application of the engine is equally important. Various engines are designed for particular functions, whether it be commercial equipment, marine vessels, vehicles, or power generators. Comprehending the desired application permits for the selection of an engine that can provide the necessary power result, torque, and operational attributes. As an example, a high-revving engine designed for performance automobiles would certainly not be ideal for sturdy construction equipment that requires high torque at low speeds.

Maintenance and Service Demands

Upkeep and solution needs play a crucial function in making certain the longevity and ideal efficiency of an engine. Normal maintenance is vital to protect against breakdowns, extend the life expectancy of the engine, and keep its performance. When choosing an engine, it is necessary to think about the supplier's advised maintenance schedule and the availability of service centers or qualified service technicians.

Variables such as the regularity of oil click this changes, filter replacements, and overall inspections can considerably impact the engine's efficiency. Some engines might need even more regular servicing based on their style and usage, while others may have longer intervals between maintenance checks. It is vital to abide by these service requirements to avoid costly repairs and unexpected downtime.

Expense and Budget Plan Factors To Consider

Spending plan restrictions frequently play a substantial function in the useful link decision-making process when picking an engine for a specific application. When considering the price and budget plan effects of selecting an engine, it is important to analyze not only the first purchase cost but likewise the lasting costs linked with maintenance, gas consumption, and prospective upgrades or fixings. It is important to strike an equilibrium between the in advance price of the engine and its overall lifecycle prices to ensure that the selected engine remains financially lasting throughout its functional lifespan.

Aspects such as gas resilience, dependability, and performance can directly impact the overall expense of possession of an engine. While a much more pricey engine might have greater ahead of time prices, it could potentially result in lower maintenance and fuel expenses over time, thus providing much better value in the future. Furthermore, thinking about the availability and expense of extra parts, along with the convenience of upkeep and service, can assist avoid unexpected economic stress in the future. By carefully reviewing these cost and budget factors to consider, you can make an educated decision that straightens with your economic restrictions and operational demands.

Final Thought

Gas efficiency refers to the engine's capability to transform gas into energy with marginal waste, straight impacting operating expenses and ecological sustainability.Variables influencing fuel effectiveness consist of engine design, combustion effectiveness, and total efficiency optimization. Additionally, selecting the proper gas kind and quality as recommended by the engine producer can additionally boost performance and extend engine life expectancy.

Engines with good service functions and easily available parts can lower maintenance costs and decrease the time the engine is out of procedure - bmw 318ti. It is essential to strike a balance between the in advance Learn More expense of the engine and its general lifecycle expenses to make sure that the selected engine continues to be monetarily lasting throughout its functional life expectancy